Executive Summary

- PipePro 450 and ProHeat System allowed welders to complete a single joint in five hours compared to eleven hours with an old propane heading rosebud and a Stick welder.

- Pro-Pulse™ modified Pulsed MIG process filled 1.25-in. wall pipe joint in just seven passes compared to 13 passes with a Stick welder.

- New technologies increased productivity by 64 percent and allowed CMN to finish the job two weeks ahead of schedule.

- Zero failures on 66 joints of ultrasonically-tested P11 heavy-wall pipe.

- Productivity increases paid for both new Miller systems on the first job.

- Pro-Pulse’s shorter arc length and more focused arc column helps eliminate undercuts, provides good sidewall fusion and fill at the toes of the welds.

CMN Steel Fabricators Find New Market With PipePro Welding System

|

|

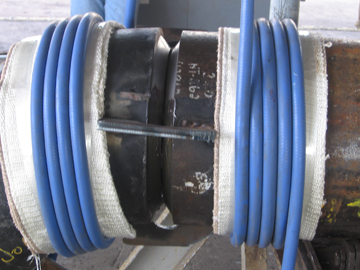

CMN Steel used the ProHeat system combined with Stick welders to weld the sections of pipe that couldn’t be welded at their shop

|

With nearly 20 years of mild steel fabrication experience under its belt, CMN Steel Fabricators decided in 2006 to forge a place for itself in the more difficult world of P11 chrome-moly pipe.

Founded in 1988 in Miami, Fl., CMN Steel fabricates structural steel and pipe for the waste energy, waste management, quarry and other industries, as well as performing maintenance during scheduled plant shutdowns. Roughly half of their 60 employees are welders.

The P11 project was the New Hope Power Partnership, an expansion of the Okeelanta Cogeneration Plant. The contract consisted of welding 66 joints of pipe made from a chromium-molybdenum alloy, specifically 1-1/4 Cr-1/2 Mo-V, commonly called P11 or “1-1/4 chrome” pipe. The P11 pipe would transport high-pressure steam between the power plant and a neighboring sugar mill.

Chrome-moly pipe is specified by the amount of chromium, molybdenum and vanadium present. Those three elements produce better creep resistance for high temperature strength, allowing the material to be lighter and thinner than carbon steel pipe while still achieving the same level of pressure capabilities for piping. However, the higher levels of those three elements in the steel make it more susceptible to cracking if not properly preheated and post-weld heat treated.

In order to prevent chrome-moly steel from becoming brittle and cracking, it needs to be pre-heated, typically between 250º and 500º F, to drive off moisture, thereby reducing hydrogen and reduce the cooling rate. Hydrogen embrittlement leads to cold cracking of the finished weld. Slowing the cooling rate reduces thermal stresses and further allows hydrogen to diffuse from the weld. Maintaining minimum temperature between passes — interpass temperature — is also necessary to continute to keep hydrogen low and reduce thermal gradients. A maximum interpass temperaturej prevents overheating the material leading to lower mechanical properties and most importantly preventing too fluid a puddle, which is difficult to control and potentially hot cracking.

Post-weld heat treatment, from 1,100º to 1,250º F, is required to reduce hydrogen in the weld and to relieve residual stress within the material that is caused by the high thermal gradients in the weld joint area and weld solidification.

New Metal, New Processes

Coming from a long line of sugar mill workers, CMN Steel President Carlos Manuel Nunez took special pride in being offered the chance to bid on the Okeelanta sugar mill job, but was also very concerned about making sure it was a success.

Chico Nunez, Carlos’ brother and a welder for nearly 30 years, began by researching the various technologies available to help ensure their success.

Chico inquired with their distributor, Julio Montecino of Matheson Tri-Gas, about the PipePro™ 450 RFC welding system, featuring Pro-Pulse™, a modified pulsed spray transfer MIG welding process, and the ProHeat™ 35 induction heating system, both from Miller Electric Mfg. Co.

“I heard about these new welding and heating products when they were first introduced, but we didn’t really have a need for such an advanced system at that time,” Chico said. “When the power plant project came up, I had a feeling that the PipePro 450 and ProHeat 35 would be the right technologies for the application.”

Three key criteria figured into CMN Steel’s decision. First, the new technologies needed to produce high quality welds. Second, operators needed to easily learn them so that CMN Steel didn’t spend more time on training than it would take them to complete the job using old technology. Third, the new technologies needed to provide a return on investment.

The decision paid off: CMN Steel completed the 1-1/4 chrome pipe project two weeks early, in six weeks instead of eight, and they reduced welding time by 64 percent. Further, every single weld passed Ultrasonic Testing (UT) on the first try; not a single one of the 66 joints required reworking. Lastly, the productivity increases paid for both new systems with this firsts job. CMN Steel’s success on the New Hope Power Partnership project has positioned the company to take on future projects using P11 and other types of high-pressure chrome-moly steel.

A Tradition of Success

Founded on the principles of a solid work ethic, CMN Steel never shies away from a challenge.

“I don’t remember my dad once saying we couldn’t do something,” recalls Marisa Nunez, Carlos’ daughter and the vice president of CMN Steel. “He’d always find a way to get the job done. That determination and belief in himself made the company what it is today, and it carries over to all of our employees.

“People bring their business to us because they know that we’re available 24 hours a day and that we take personal pride in all the work we do,” Marisa continued.

Another key ingredient to CMN Steel’s success has been Julio Montesino, the company’s Matheson Tri-Gas representative since 1991. Montesino has outfitted the company with welding generators, wire feeders, multi-process power sources, plasma cutters and more over the course of their relationship.

“We have complete faith in Julio. He’s there for us at the drop of a hat if we have a question about something, and he’s never recommended a product that didn’t work out,” Marisa said, “so we knew he would give us a straight answer when it came to whether these new welding and heating systems would meet our needs.”

Montesino recalls, “I knew right away the PipePro 450 and ProHeat 35 would be good for CMN Steel because they are user-friendly and deliver results better than older technology.”

64 Percent Improvement

The Okeelanta Cogeneration Plant, one of the largest of its kind in the country, uses sugar cane stalks to produce bagasse, a biomass fuel that is in turn used to create steam in the production of electricity at the power plant. In return for the bagasse produced by the sugar mill, the power plant sends along the steam it creates for use in the sugar mill’s operation. The result is a symbiotic and environmentally friendly relationship in which each partner benefits from the others’ waste material — the power plant from the sugar cane stalks and the sugar mill from the excess steam from the power plant.

The expansion called for 280 feet of Schedule 160, 12-in. diameter, 1.25-in. thick P-11 pipe with 66 joints beveled at 35 degrees. Welding Procedure Specifications called for the root, hot and first fill passes to be performed with TIG, using 1/8-in. diameter ER80S-B2 filler metal with a 3/32-in. or 1/8-in. thoriated tungsten electrode and pure argon shielding gas.

|

|

The specifications provided by the engineers for the New Hope Power Partnership project required TIG welding the first three passes of the pipe.

|

The Stick specifications called for an additional 15 passes using 1/8-in. E8018-B2 electrodes. By comparison, the pulsed MIG process specifications allowed the company to nearly halve the number of required passes. They were still required to make the first three welds using TIG, but the increased deposition rates of the Pro-Pulse process compared to Stick (< 3 lbs./hr for a 1/8-in. E7018 electrode for Stick vs. 4.5 to 14.4 lbs./hr for an .045-in. ER70S-6 electrode for Pulsed MIG) allowed them to fill the rest of the joint with just seven more passes.

Each joint also required a 300 degree F preheat, a 450 degree F interpass temperature and maintaining a 1150º F post-heat treatment for 1-1/2 hours. Each joint required UT.

For the joints that needed to be heated and welded on in the field, the company used a propane rosebud heating method and Stick. With those processes, it took Chico 11 hours to complete a single joint. Using the PipePro and ProHeat systems, it took him 5 hours per joint, a 64 percent improvement.

This productivity increase also pleased the welders, who were given the choice of getting paid per hour or per piece. They naturally chose piecework.

“Our welders were used to 12-hour days,” Marisa said. “On this project, they were able to earn the same income in six hours that they would normally make in 12 hours. They were very happy with the results.”

New Pulsed MIG Technology

The PipePro’s Pro-Pulse feature is a modified spray transfer process that monitors, controls and adjusts the current hundreds of times faster than other pulsing technologies.

Pro-Pulse technology controls both current and voltage (see graphic) to stay within the optimum range for a specific wire type and diameter, wire feed speed and gas combination. The Pro-Pulse control scheme starts by ramping up the current. Once the target current is reached at the beginning of each phase, the constant current (CC) control turns off and the constant voltage (CV) control loop turns on. The CV loop modulates the current within a range that maintains the target voltage. This occurs independently of the contact tip to work distance. The system can monitor and adjust parameters up to 10,000 times per second to maintain optimum arc conditions.

The PipePro 450 also simplifies training because it adapts to individual operator preferences and does not force the operator to adapt to the machine. Typically, operators prefer to hold a short stick out ¾ about 3/8 inch for short circuit MIG and 5/8 inch for flux cored ¾ because it gives them better control over the molten weld puddle.

With older pulsing technology, different arc lengths sound, feel and look different. Conversely, the PipePro 450 maintains optimum arc length and weld parameters, even if operators vary travel speed or electrode stick-out within a broad range (stick-outs up to 1 in. are possible). This is a big benefit when welding in deep grooves or when operators shifting welding positions, such as when moving from the bottom to the top of the pipe. It can alleviate arc stumbling, subsequent porosity and the need to waste an hour grinding out a bad weld and repairing it.

In the past, the limits of available technology forced operators to weld with a longer arc length to help prevent short circuits, resulting in spatter (encountering a tack weld was a common culprit). Holding long arc lengths also had a tendency to produce undercut if travel speeds were not reduced. Pro-Pulse’s shorter arc lengths and more focused arc column help eliminate undercuts, providing good sidewall fusion and fill at the toes of the weld. CMN Steel’s zero reject rate testifies to the ability of the pulsed MIG technology to consistent produce sound welds.

Lastly, the PipePro lowers overall heat input, which can reduce interpass cooling time and weld cycle time. When welding thick-wall pipe that requires multiple passes (such as the seven passes CMN Steel needed to weld the 1.25-in. thick P11 pipe), reducing interpass cooling time may save an hour or more per joint.

A Revolution In Heating

Complementing the productivity improvements of the new MIG process, the ProHeat 35 allowed CMN Steel to save considerable time in pre- and post-weld heat treatment with a level of heat consistency and safety not possible with other heating methods.

“Induction heating is the way to go,” Chico said. “Induction is faster than using rosebuds or ceramic blankets and gives us greater control over the ramping rates than other methods. Plus, the heat is concentrated at the place of the weld, so you don’t have to worry about touching the pipe in other places.”

Induction heating differs from other heating methods in that it uses an electromagnetic field to heat the metal from below the surface without actually contacting the material. Other heating methods, such as resistance heating, use a heating element that is in contact with the material to heat the pipe from the surface.

The electromagnetic field excites the molecules within the material, which in turn generates heat at a much faster rate than other systems, allowing it to reduce cycle time by up to two hours on thick sections of pipe.

|

|

This section of pipe is tacked up, wrapped with the ProHeat’s insulation blankets and induction coils and is ready to be welded.

|

The ProHeat 35 system can be air-cooled or liquid-cooled, but for high-temperature post-weld treatments, as was necessary for the sugar mill job, a liquid-cooled system is required.

Designed for preheating, hydrogen bake-out and postheat stress relieving applications up to 1,450° F, the liquid-cooled system differs from the air-cooled system in that it houses the heating coils in flexible, liquid-cooled hoses instead of heating blankets encased in a protective Kevlar sleeve.

The system also features an easy-to-use built-in temperature controller with multiple thermocouple inputs for precise and uniform heating.

Setting up and installing the ProHeat 35 usually takes less than 15 minutes, with minimal training involved, adding to the system’s time saving features.

The ProHeat 35 also provides a safer work environment compared to methods using flammable gases or high temperature electrical connectors. Because the heat is generated by the electromagnetic field and only affects nearby metal, the induction coils themselves do not get hot.

A Bright Future

With other projects keeping them busy, CMN Steel hasn’t had the time to take on any more high-pressure steam line jobs like the sugar mill. With their proven performance at the New Hope Power Partnership, though, there’s no question that they have found themselves a new industry in which to continue their tradition of success and growth.

“This experience has shown us and potential employers that we are capable of welding high-pressure chrome-moly steel where all joints pass UT inspection without rework,” Marisa said. “Our performance on the New Hope Power Partnership project gives us the credentials and confidence to bid on jobs involving other types of chrome-moly steel as well.”