Heavy Repair Contactor Relies on Miller's Lightweight Maxstar® 150 Stick/TIG welder

Print Article

Big Iron and other large weldments weigh more than 100,000 lbs., but sometimes, all you need is a 14-lb. portable Stick welder to repair them, especially when site access is an issue.

Heavy repair contactor relies on lightweight Maxstar® 150 Stick/TIG welder

|

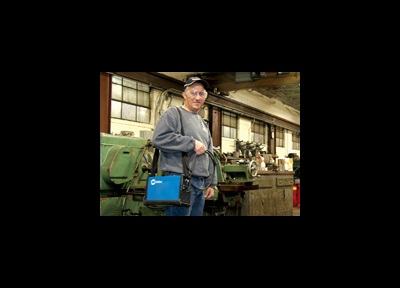

| THROW-N-GO FOR MRO: For portable welding inside an industrial facility, up in a man-lift or for field repairs, just throw the 13.7 Maxstar® 150 Stick/TIG welder over your shoulder and head to the job site. This welder provides 5 to 150 amps of welding output and connects to both 115 and 230 V power without any tools. |

FEMCO Machine Company (www.femcomachine.com) specializes in the repair and refurbishment of heavy equipment in the scrap, mining and aggregates industries. The company has two large machining and welding facilities (Punxsutawney, Penn. and Pompano Beach, Fla.) and 17 service trucks. Onsite work requires 6,000-lb. truck-mounted cranes, diesel welder/generators, magnetic drills and a whole roster of machining equipment to restore large equipment to OEM specifications.

Although the work is heavy, one of the company’s newest tools is light enough to be thrown over a shoulder.

“The convenience of the Maxstar® 150 welder can’t be beat,” says Ray Pierce, FEMCO’s assistant field service manager. “It works really well in places where access is difficult, such as getting in and out of buildings.”

The Maxstar150 weighs 13.7 lbs., making it Miller Electric Mfg. Co.’s most portable welder. While compact, this unit is no lightweight when it comes to Stick and TIG welding. It provides up to 150 amps of welding power at 30 percent duty cycle, more than enough output to run 3/32- and 1/8-in. Stick electrodes.

“We don’t need a rod larger than 1/8-in. to repair small cracks or to weld small bores,” says Pierce. He also reports that the Maxstar 150 helps when working out of a man-basket 60- to 80-ft. up in the air. “Running weld cable would leave a lot weight hanging down, but the Maxstar’s very light and convenient to take up in the man-lift. It also saves the man. He’s not as tired at the end of the day.”

For convenience when moving between job sites, Maxstar 150 features Miller’s Auto-Line™ power management technology, which automatically connects the unit to 115 to 230 V single-phase power. Further, Miller’s multi-voltage plug (MVP™) allows using both115 or 230 V receptacles; simply twist the right plug on or off, no tools required.

“In the past, we spent a lot of time stretching welding leads, trying to borrow a welder off of a customer or haul one of our electric machines to the work site. We’d out go through all that just to do a small amount of welding. It was a lot of extra work and time. Now we’re going to run the Maxstar–it’s obvious.”

Visit www.MillerWelds.com for more information on welders for maintenance and repair operations.