Tech Talk: Auto-Line™ Technology Eliminates Dirty Power Woes To Produce Rock Steady Arcs

Print Article

Exclusive Miller technology helps solve problems with dirty power in the shop and in the field.

(As seen in Applied Welding, Issue 2, 2004)

Q: What is dirty power?

A: Fabricators, contractors and manufacturers often fight weld quality and maintenance problems that result from primary voltage fluctuations, or “dirty power.” Dirty power is the result of unreliable primary power—large motors starting on the same primary power line, utility brownouts or spikes, and generators that do not regulate auxiliary power voltage.

Q: How does dirty power affect weld quality?

A: A power surge or dip can cause your arc to flicker and your inverters to shut down for self protection. In some cases, you might not even know you experienced dirty until the QA/QC department rejects your weld because it doesn’t pass inspection.

Q: What can I do to protect my work from dirty power?

A: Miller has developed its exclusive Auto-Line power management technology that frees operators from primary power limitations and allows uninterrupted production. Auto-Line is featured in Miller’s Axcess™ Series of multi-MIG inverters; TIG inverters such as the Maxstar® 150 and 200 Series and Dynasty® 200; multi-process inverters such as the new XMT® 350 CC/CV; and plasma cutters such as the Spectrum® 2050.

Q: How does Auto-Line work?

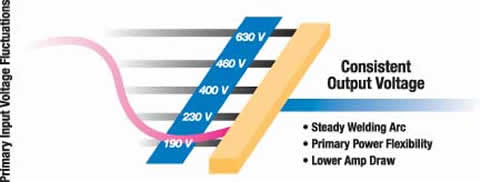

A: Auto-Line technology uses what’s known as a “boost converter.” This circuit boosts primary input power—from 190 through 630 V or anywhere in between— to a higher voltage. This voltage then charges a capacitor, which is a device used to store and quickly discharge energy. Power for the actual inverter section of the welder comes from this capacitor. The inverter, therefore, has sufficient power as long as the primary power remains within a +37/-59 percent of the nominal 460 V power. In short, it’s like drawing water from a well that’s always full.

Q: What does Auto-Line do for weld quality?

A: Auto-Line ensures that you always draw welding or cutting power from a regulated, stable voltage source within the machine, which lets you ride effortlessly through dirty power. Auto-Line gives a rock-steady arc, “on spec” welding parameters and equipment with an incredibly dynamic, link-free operating range.

Q: What is the difference between Auto-Line and Auto-Link?

A: They’re both examples of great technology from Miller. Auto-Line automatically and continuously adjusts for voltage surges and drops, providing a constant, steady arc and ensuring quality welds. Auto-Line does this regardless of input voltage, provided it is within the operating range of the equipment being used. Auto-Link “links” power, switching transistors for either 230 or 460 V primary power only.

Q: How do I know if an Auto-Line equipped inverter fits my needs?

A: Auto-Line is for anybody who can’t afford re-work. And Auto-Line also gives you the flexibility to use the same machine in the shop and in the field because it smoothes out power fluctuations anywhere.