Address causes of burn-through

If you weld sheet metal and use conventional welding equipment, you know the challenges of welding this material — obtaining good fusion while simultaneously controlling:

The key word here is control. While thicker sections of metal might not need advanced control, sheet metal offers little room for error, but lots of room for improvement. Take welding aluminum, for example.

Causes of burn-through in welding aluminum

Selecting a weld process for thin aluminum is like the story of Goldilocks tasting porridge. Short-circuit MIG is too cool and subsequently prone to cold lap (aluminum’s excellent thermal conductivity transfers heat away from the weld area before good fusion can occur). Spray transfer MIG is too hot and prone to burn-through, especially on the back of the weldment or when gaps exist. AC TIG, the process traditionally selected to weld thin aluminum, has the slowest travel speeds; this increases cycle time and heat input, which makes the weldment prone to warping.

How to prevent burn-through when MIG welding

Fortunately, pulsed MIG technology is just right for welding thin aluminum. Pulsed MIG gives users:

- The ability to control heat input. The pulse of peak current provides the good fusion associated with spray transfer, while the low background current cools the weld puddle and lets it freeze slightly.

- Good travel speeds. Switching from AC TIG to pulsed MIG can increase travel speeds significantly while cutting heat input.

- The ability to control bead profile. Using a simple function called arc control, operators can adjust the characteristics of the arc cone, which lets them tailor the arc to the application. A softer arc cone can help tie in both sides of the joint or the outside corner, while a stiffer arc provides good fusion at the root of the joint.

As a practical example of how pulsed

MIG can benefit welding thin aluminum, consider the case of Alum-Line, an Iowa trailer manufacturer. This company

addressed production issues on two different components by switching to pulsed MIG technology.

In the first area, which involved welding .125-inch wall aluminum tubing using spray transfer MIG, burn-through often occurred when part fit-up was less than optimal. Cycle time was about 60 minutes. Switching to pulsed MIG reduced cycle time to approximately 30 minutes, largely by eliminating rework.

|

|

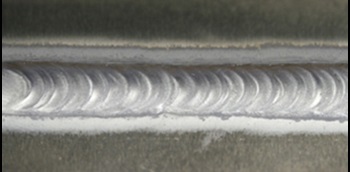

| Fig. 1 — Bead comparison: Fabricators can substitute pulsed MIG for AC TIG on aluminum because it maintains bead aesthetics while increasing travel speeds and lowering heat input. The top image shows an AC TIG bead, while the bottom image shows a Profile Pulse™ bead. The Profile Pulse feature is available on select Miller® equipment, including AlumaFeed®, Continuum™ and MPa+ feeder systems. |

In another area, Alum-Line made long TIG welds on .080-, .100- and 1/8-inch aluminum diamond plate. Here, the operator fought warping. After switching to pulsed MIG, the operator increased travel speed by 30 percent, maintained good bead appearance (see Fig. 1, Bead Comparison) and solved warping issues by reducing heat input. Most importantly, Alum-Line operators in both areas learned to weld with the new pulsed MIG technology after just a few hours of training.

Manufacturers developed new pulsed MIG welding systems to overcome operator training and acceptance issues. Pulsed MIG always held great promise, but older technology forced operators to hold a long arc length to avoid unintentional short circuits and arc re-strikes. Unfortunately, holding a long arc makes it difficult to control the weld puddle, and becoming proficient can require weeks of training time. Old technology forced the operator to adapt to the machine — and many operators refused to adapt.

Conversely, with new technology, arc lengths can be run closer to the puddle, giving the operator more control than what was available with older welding equipment. Secondly, this new technology allows the operator to vary stickout without varying arc length. This means operators can hold a longer electrode stickout to weld in deep corners and the system will maintain the arc length.

Newer technology eliminates the hassle of programming pulsing variables in most applications. Operators set arc length and wire feed speed they are comfortable with. Once an arc length is set, the system’s synergic control allows that arc length to be maintained across the range of wire feed speeds, so the operator doesn’t have to change the arc length again. Even if the operator goes from 200 inches per minute to 600 inches per minute, arc length stays the same. The only variables operators have to adjust are arc length (voltage), wire feed speed (amperage) and arc control (should operators choose to fine-tune arc characteristics), and these are adjusted by simple control knob and digital display.