H.L. Lyons (Louisville, Kentucky) helped U.S. appliance manufacturers kick-start the “stainless steel revolution” that has made its mark on almost every commercial and residential kitchen in the country. A major appliance manufacturer approached the company in the early 1990s to skin the doors of a refrigerator with stainless steel—an idea that originated at a European trade show. The prototypes were a success and the manufacturer made a gross underestimation by stating that “maybe we’ll sell 20 of these per month.”

|

|

H.L. Lyons helped U.S. appliance manufactures kick-start the stainless steel revolution touching almost every commercial and residential kitchen in the country.

|

That number soon became 400 per week. Then it rose to 2,000 per week. As the demand kept rising, Keith Lyons, co-owner, H.L. Lyons, kept looking for new and improved ways to weld and polish stainless steel efficiently. It wasn’t until Lyons commissioned brand new Dynasty® 300 DX AC/DC TIG/Stick welding inverters from Miller Electric Mfg. Co. that the company realized its optimum productivity in stainless steel refrigerator door production: 12,000 doors per week. The new system has cut welding time in half, reduced finishing time by a third and allowed each welder to finish almost twice as many doors per shift.

Advances in Pulsed TIG Welding Spurs Productivity

H.L. Lyons does more than design stainless steel refrigerator doors. The company has built a niche for itself in supplying fabricated stainless steel structures to a variety of industries: appliance manufacturers, retail outlets and transportation companies to name a few. Lyons credits the substantial growth of his family’s business to the increasing demand for stainless steel components and the technological advances that have made it easier to fabricate that material.

“What really got us into the stainless steel business was the ability to weld and polish stainless steel,” claims Lyons. “We are able to TIG weld these components and polish them to look like it has never been welded.”

|

|

The use of a stainless steel skin on refrigerators was an idea that became popular at a European tradeshow in the early 1990s.

|

H.L. Lyons begins refrigerator door construction with large sheets of 22 gauge (less than .03-in.), grade 304 stainless steel. Grade 304 stainless steel is used for its ease of forming, welding, and its resistance to corrosion. The company uses two automated forming cells to bend and spot weld the stainless steel refrigerator doors into shape. Each door is then moved to one of five welding stations where the seams at each of its corners are manually TIG welded together without filler metal.

The challenge of welding thin stainless steel is achieving adequate penetration without overheating it. Unlike other metals, stainless steel does not adequately dissipate heat when welded; it holds heat in the area where the welding arc is concentrated. The concentration of heat can cause two major problems with thin stainless steel: warping and rust. Warping usually leads to a part being scrapped, which is a costly waste.

Further, temperature ranges of 950 to 1850o F or higher can also cause stainless to become brittle, as well as decrease its corrosion resistance in the heat-affected zone. Excess heat concentrates the carbon in stainless steel, where it will be trapped when the metal cools. Given time, the area overloaded with carbon will rust. This phenomenon is commonly called Carbide Precipitation or “burning out the chrome.” Burning out the chrome could lead to rusting—stainless steel’s best-known property—which may, in turn increase a manufacturer’s warranty costs.

Depending on the end product, a single warranty claim could cost hundreds or thousands of dollars; an upgrade to a TIG inverter not only provides improved production quality, but also an instant return on investment.

H.L. Lyons solved these problems with pulsed DC TIG welding, where the power source “pulses” between a high peak amperage and a low background amperage (see story in tint box). The peak amperage is what it takes to melt the part, and the background amperage keeps the weld puddle fluid as it cools, giving the operator more control: the combined effect of alternating high and low amperage levels produces better control over penetration, bead width, crowning, undercutting and heat input. All the factors that affect weld quality.

“Our heat-affected zone is a lot smaller (with pulsed TIG),” says Lyons. “The arc is a lot more controllable. These welds were difficult to do with the conventional TIG process. We have to use pulsed TIG.”

|

|

After the sheet of stainless moves through a robotic press, corners are spot welded creating the door seen here.

|

Prior to buying the Dynasty 300 DX inverters, H.L. Lyons used the Syncrowave® 250 DX, a conventional technology TIG machine with a pulsing range of .25 to 10.0 pulses per second (PPS). The Dynasty 300 DX using inverter technology that enables controlling the welding output in much finer increments, and doing it much faster. As a result, the Dynasty 300 has a pulsing range of .1 to 500 PPS (and note that the new Dynasty 700 and Maxstar® 700 models can pulse at frequencies up to 5,000 (five thousand!) times per second).

H.L. Lyons currently sets its Dynasty inverters at 175 PPS with a peak amperage output of 40 amps, a peak arc-on time of 75 percent and background amperage set to 20 percent.

|

|

At 10 pulses per second, conventional TIG technology allowed more heat into the material, as seen by the heat affected zones blue-ish coloring. Eliminating the discoloring required a time-consuming post-weld grinding process.

|

The higher pulsing rates of a TIG inverter increase puddle agitation, which in turn produces a better grain molecular structure (strength) within the weld. Pulsing the current at higher speeds also constricts and focuses the arc. This produces a smaller heat-affected zone and increases arc stability, penetration and travel speeds. These benefits have reduced scrap and increased production rates at each of the company’s five welding stations with the Dynasty 300 DX inverters.

Post-Weld Cleanup Reduced Dramatically

“We’re welding about twice as many doors, but what was really important was the fact that it allowed us to finish doors faster because the welding was so much better,” says Lyons.

In addition to an easier and faster welding process, H.L. Lyons’ operators no longer need to grind away excess weld bead material after completing the weld because inverter technology enables them to maintain an optimum balance between bead width and penetration (which also which ensures optimum weld appearance and strength). The post-weld clean-up ritual with the previous TIG welder consisted of three steps: grinding, polishing and graining. Now, each piece is polished, grained and sent out the door. Lyons says that the benefits are obvious.

|

|

Post-weld grinding was more common using conventional TIG technology for H.L. Lyons to create a solid, clean looking corner.

|

“It’s a significant reduction in my production costs. We’ve reduced the welding time by half and reduced the finishing time by a third.”

To put it in production terms, each welding station previously averaged between 50 and 60 stainless steel refrigerator doors per shift. After switching to the Dynasty 300 DX four years ago, Lyons’ operators began averaging 120-130 doors per shift. That increase in productivity without adding to labor and more than makes up for the additional cost of inverter technology.

“We’ve had up to 12,000 doors in here per week,” say Lyons. “We were able to produce the same amount before, but it would have taken more people, more machines and more grinders.”

Additional Benefits Achieved with Inverter, Accessories

In addition to its pulsing capabilities, the Dynasty 300 DX provided additional welding efficiencies. This TIG inverter can store four DC pulsed TIG programs and also features last procedure recall. Both features eliminate guesswork and allow operators to recall previously approved programs for welding at their station. This helps reduce scrap and ensure consistency from station to station; setting welding levels is as simple as pushing a button.

|

|

The appeal of stainless steel in kitchen design has not lost its luster as seen by this lineup of finished refrigerator doors.

|

The inverter technology that powers the Dynasty 300 DX draws considerably less amperage than conventional TIG machines. This helps reduce H.L. Lyons’ power consumption, a considerable savings when you consider that there are five Dynasty 300 DX inverters working three shifts per day to build stainless steel refrigerator doors. These inverters can also plug into 230 V or 460 V single- or three-phase power without removing the covers and having to re-link the power source thanks to Miller Electric’s Auto-Link™ technology. This feature makes it easy to plug the machines in anywhere and begin operating within in minutes.

H.L. Lyons has also effectively reduced the consumption of argon shielding gas it uses in the pulsed DC TIG welding process by implementing a two-stage, H1400 series gas flow regulator from Smith Equipment. The two-stage regulator eliminates the big surge of gas at the beginning of the weld sequence. This makes the arc start a lot smoother, causes minimal disturbance to the weld puddle, and reduces gas consumption by nearly two thirds. H.L. Lyons gets almost one full week out of an argon tank now compared to three tanks per week when the company relied on single-stage regulators. This reduces consumption and the costly downtime associated with switching cylinders. H.L. Lyons has also outfitted each of the Dynasty 300 DX inverters with Weldcraft Crafter Series™ TIG torches to further optimize shielding gas effectiveness and overall operator control.

Conclusion

By replacing conventional TIG welding technology with new Dynasty 300 DX inverters, H.L. Lyons has given its employees the power to produce a quality product in less time. In an age where the price of steel has left many businesses hamstrung, H.L. Lyons has found new and powerful ways to reduce production costs and remain competitive. It’s only one of many improvements that the company has made to drastically increase its overall production.

|

|

The H.L. Lyons production floor is a flurry of activity capable of producing 12,000 stainless steel refrigerator doors per week thanks to the inverter power of Miller’s Dynasty 300 DX.

|

“We’re actually assembling now, on one shift, about 30 percent more than we did on three shifts last year,” says Lyons. “The product we produce is engineered much better and we’ve provided our employees with excellent work stations. We’ve made a lot of advances.”

Sidebar Article

Reducing Heat Input

The pulsed TIG capability of the Dynasty 300 DX enabled H.L. Lyons to double production and improve in weld quality at the same time. Manufactures using stainless steel are primarily concerned with warping, weld bead appearance, color and weld integrity, all of which pulsing helps control.

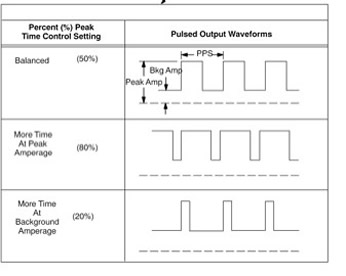

Pulsed TIG welding minimizes heat input through the “on and off pulsing action” of the arc (see Fig. 1). Note that while pulsing creates an audible difference between “regular” TIG, pulsing rates of even 30 PPS won’t be visible to the eye (for example, the lights in your house go on and off 60 times per second because of the 60 Hz AC wall power, yet you perceive the bulb as a constant source of light).

|

| Fig. 1 The operator sets four variables when programming a pulsed TIG output: peak amperage, background amperage, pulses per second (PPS) and peak time. |

PPS is simply how many times the machine will

complete one pulsing cycle in a time span of one second. This feature enhances weld cosmetics and reduces heat input, thus reducing warping. Increasing the number of pulses per second produces:

* A smoother the ripple effect in the weld bead

* Narrows the weld bead

* More “cooling effect”

Reducing the number of pulses per second widens the weld bead. Slower pulsing also helps agitate the puddle and release any porosity or gas trapped in the weld (this is very helpful when welding aluminum with AC pulsed TIG). Some beginning TIG welders use a slow pulsing rate (perhaps .25 to 1 PPS) to help them develop a rhythm for adding filler metal. When beginners weld aluminum, an AC pulsed TIG rate of about 4 to 8 PPS may enhance cosmetics too. However, an experienced TIG welder may set a much higher PPS rate. It is not uncommon for them to weld aluminum at 4 to 130 PPS and stainless steel at 100 to 500 PPS (rates higher than 500 PPS are generally automated).

The peak time (“PEAK t” on the Dynasty control panel) is simply the percentage of time during one pulsing cycle the power source spends at the peak amperage (main amperage). With peak time of 60 percent and a rate of 1 PPS, the Dynasty will spend 6/10ths of a second at peak amperage and 4/10ths of a second at the background amperage. Increasing the peak time percentage adds more heat to the part, while decreasing peak time percentage reduces heat. A good place to start for peak time is 50 to 60 percent.

The background amperage (“BKGND A” on the Dynasty control panel) will be a percentage of the main amperage set on the machine. Thus, a machine set for an output of 200 amps and a background amperage of 50 percent produces a background amperage output of 100 amps during the background side of the pulse. This feature helps keep heat out of the part. Lowering the background amp percentage reduces the average heat input, while increasing the background amp percentage raises the overall amperage. When adjusting this feature, operators will especially notice how it affects weld puddle fluidity during the background portion of the cycle. Overall, operators want to shrink the puddle to about half its normal size while still keeping the puddle fluid. When welding stainless and carbon steels, start by setting the background amperage at 20 to 30 percent of peak amperage; on aluminum alloys, set the background to 35 to 50 percent of peak.

Note that experimenting with PPS, Peak and Background Amperage is the only way to determine the parameters that work best for your specific application. For best results, only adjust one variable at a time. As noted earlier, those using pulse TIG welding in an industrial setting will benefit most from inverter technology. Where a conventional TIG machine is limited by the 60 Hz primary power, an inverter essential creates its own internal operating frequency, which is typically 20,000 to 60,000 Hz. This speed translates into significantly greater arc control, arc focus and arc stability—all things professional TIG welders demand!

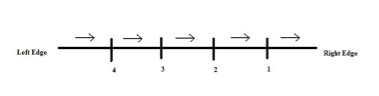

Backstepping Technique

In additional to pulsed TIG welding, H.L. Lyons uses a technique called “backstepping” to further reduce heat when TIG welding thin stainless steel (see Fig. 2). The standard practice when TIG welding is to push the weld puddle in one continuous direction for the entire length of the weld. With backstepping, however, the welder breaks up the seam in sections to further dissipate the heat. As shown in the diagram, an operator starts at position 1 and welds out to the right edge. He/she would then move to position 2 and weld out to position 1, and so on.

|

| Fig 2 |