Selecting The Right Portable Wire Feeder

Print Article

When shopping for a new wire feeder, one of the first things you need to determine is where you're going to be doing most of your welding. If you're going to be crawling through a porthole at the shipyards on Monday, driving out to a remote construction site on Tuesday, and back in the shop on Wednesday, then your best bet is a portable unit. Once you've established that you need a portable wire feeder, next you'll want to examine which type of feeder best suits your needs.

Rugged suitcase feeders

Portable or "suitcase-style" wire feeders are designed for operators in rugged conditions who need a feeder that will stand up to the elements and get in and out of tight spaces. To that end, suitcase feeders feature crush-proof, flame retardant cases that protect internal components from dirt, moisture and contaminants. How effectively they accomplish this varies greatly between models. Miller's SuitCase® VS and RC series feeders (SuitCase® 8VS and X-TREME™ 12VS, 8RC and 12RC) offer unmatched performance. In fact, they feature the same casing technology the military uses to protect cameras and digital hardware.

|

| Millers SuitCase X-TREME 12 VS feeder features a single voltage sensing lead for job site convenience. Note the digital meters (fig 1). |

Able to hold either an 8-in. or 12-in. diameter spool and run .023- to 5/64-in. diameter wires, you'll find suitcase feeders most often in construction, shipbuilding and mechanical contracting (especially maintenance/repair) where portability and protection are absolutely essential. They can measure as little as 14.5 in. high by 6.5 in. wide by 15-5/8 in. long, slim enough to allow easy movement through tight portholes, manholes or crawl spaces. Suitcase feeders can weigh anywhere from 22 to 35 lbs. when empty (weight varies significantly, so check each model carefully).

Voltage sensing or constant speed wire feeder?

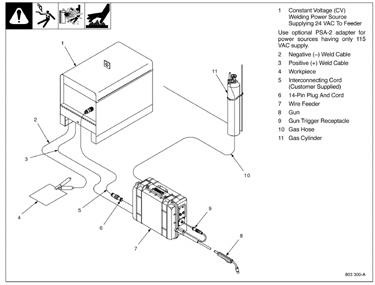

Suitcase wire feeders come in two categories: voltage sensing and constant speed. Voltage sensing feeders, such as Miller's SuitCase 8VS and X-TREME 12VS, operate on arc voltage. This eliminates the need for a control cord between the power source and the feeder (see Fig. 1). Many operators feel the extra cord is just one more item to carry, lose or damage.

A voltage sensing wire feeder can be paired with either a constant voltage (CV) or a constant current (CC) power source. Note that these feeders typically have a CC/CV switch inside the case. Be sure it is in the right position before welding.

With a voltage sensing wire feeder and CV power source, voltage is set at the power source while wire feed speed (amperage) is set at the feeder. This can present a headache when working remotely from the power source, such as up on scaffolding and when you need to adjust voltage. Also, because voltage varies directly with distance between the electrode and the work piece (arc length), the feeder attempts to regulate voltage variations (e.g., an unsteady hand) by controlling wire feed speed. This means your parameters can vary slightly.

CC power sources, most notably older "DC generator" style engine drives, are designed for Stick/TIG welding. In the past, contractors often adapted them for spray transfer MIG and flux cored welding by adding a voltage sensing wire feeder (short circuit MIG is very limited with this set up). Today, many engineering firms, construction companies and building codes no longer allow flux cored welding (FCAW) with a CC power source. It does not provide adequate assurance that the weld is being made with the proper voltage because operators must hunt for a voltage because the voltage fluxuates on a volt/amp curve from the CC power source (see Fig. 2).

Instead, experts recommend a CV power source for wire welding, especially for the nickel-alloy and other flux cored wires used for structural welds on buildings and bridges. These wires are very voltage sensitive and generally require the fine-tuning capabilities of a CV machine.

|

|

| RC FEEDER CONNECTION (fig. 2) |

|

Constant speed for remote control

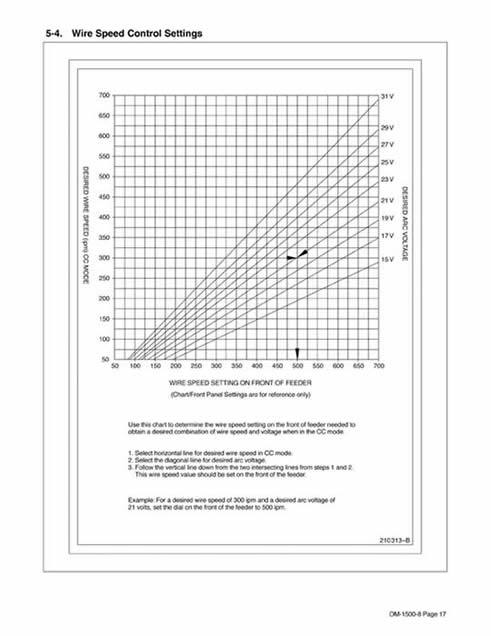

A constant speed wire feeder, such as the Miller SuitCase 8RC and 12RC, is used only with a constant voltage (CV) power source. This arrangement requires an extra control cord between the feeder and the power source, but that allows operators to control both voltage and WFS (amperage, see fig. 3) at the feeder, a big benefit when working remotely (see fig. 4). Further, voltage and amperage values remain constant unless manually adjusted, and both can be adjusted independently of each other.

|

| Volt/amp curve (fig. 3) |

When welding procedures specify wire feed speed and voltage, a constant speed feeder may be your best choice. When you set the controls for a wire feed speed of 250 inches per minute, that's what the system delivers. Wire feed speed does not vary like it does with a voltage sensing system. Both VS and RC feeders have digital meters, typically an option, make setting e xact parameters easier. The meters display wire feed speed or volts (one at a time) or they can be set to display amps or wire feed speed (one at a time).

|

| Remote control. These operators use a wire feeder with remote control so they do not need to return to the Miller Du-Op engine drive to adjust parameters, which they do when changing welding positions (e.g., flat, vertical up or overhead) or wire sizes (fig. 4).

|

Additional criteria

When examining suitcase style feeders, other features to look for include a quick connect on the voltage-sensing lead that will disconnect if pulled excessively without damaging internal components. This solves a common maintenance problem on older units. The same holds true for metal guards on the front panel to control knobs from impact damage. Carrying handles that fold down also prevent damage, and they should be large enough for a gloved hand to carry.

To reduce fatigue when making the long welds common in the construction and shipbuilding industries, consider feeders with an optional trigger-hold that allows operators to relax their index finger during the weld cycle.

And here's something else to consider: Operators with larger hands should look for a wide, easily accessible drive roll area when they're installing a new spool of wire, adjusting tension or changing drive rolls. When examining the internal components, look for an all-gear driven drive roll system. This means that both rolls have power to push the wire (as opposed to systems with an idler wheel).

A good drive roll system should not require you to apply too much tension as this crushes the wire and causes excess liner wear. To test if your current system is crushing the wire, disconnect the gun from the front of the feeder, remove the wire and blow into the liner. If a big cloud of "dust" comes out the contact tip (actually metal shavings) and you've been replacing the liner often, chances are a excessive drive roll tension is the culprit.

In summary, when assessing the various portable wire feeders, you'll want to consider the following key features:

- Type of power source paired with the feeder

- Convenience (voltage sensing) vs. remote control (constant speed)

- Durability

- Weight and balance

- Ergonomics (carrying handle, tension adjustment, trigger hold)

- Easily serviceable

- Overload and over-heating protection (SuitCase feeders have a unique thermal shutdown feature)

Lightweight spool guns

Spool guns, featuring a pistol grip and 4-in. diameter wire spool mounted on the back end, also provide mobility. Though most commonly used for welding aluminum because they solve the feeding problems encountered by push-only systems, some contractors and fabricators also use them for running a second type of wire (e.g., stainless steel or a smaller diameter solid wire). With 15- or 30-ft. cable options, spool guns also provide mobility when working around large weldments, such as a trailer.

Miller offers two classes of spool guns. The Spoolmatic® 15A and 30A (see fig. 5) work with CC or CV power sources and contain features designed for professional, heavier duty applications. The Spoolmate™ 3035 and 3545 work with CV power sources and are designed for light industrial applications.

|

|

Spoolmatic flexibility. This operator fabricates an aluminum weldment with a Spoolmatic 30A in the shop and can easily use it in the field for installation work

(fig. 5).

|

Think ahead

In selecting a wire feeder, allow for flexibility, growth and future needs. Don't make the mistake of just thinking about how you're using your welder now. Instead, think about how you'll be using it three or five years from now. Consider a wire feeder a long-term investment and make some calculated projections.

Discuss your needs with your distributor, who can direct you toward models that include the functions and abilities you'll need. Distributors can help first-time buyers find a wire feeder that you can tailor to your specific application. If you're experiencing issues with you current feeder, it may be time to upgrade your feeder — and your profitability.