Tech Talk: Auto-Line Technology Offers Location Flexibility To On-site Welders

Print Article

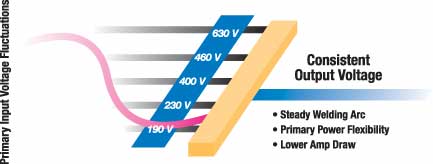

Questions and answers on Miller's exclusive Auto-Line™ technology and how it provides consistent welding performance in the field.

(As seen in Applied Welding, Issue 3, 2004)

Q: What is Auto-Line technology?

A: Auto-Line™ technology uses what’s known as a “boost converter.” This circuit boosts primary input power to a higher voltage. This voltage then charges a capacitor, which is a device used to store and quickly discharge energy. Power for the actual inverter section of the welder comes from this capacitor, which means that Miller inverters with Auto-Line are not directly dependent on any one type of primary power.

|

| Wonder what type of power will be available at your next job site? Miller’s unique Auto-Line circuitry eliminates that concern because it enables plugging into any type of outlet. |

Q: What are some of the benefits of Auto-Line technology?

A: Permitting direct connection to almost any type of input power from 115V to 575V, single or three-phase, 50 or 60 Hz, Auto-Line allows you the flexibility to weld anywhere in the world. Auto-Line products are also lightweight, eliminating the need for forklifts and cranes to obtain maneuverability. In addition, Auto-Line provides better weld quality and uninterrupted production by continuously compensating for line voltage fluctuations.

Q: What types of organizations benefit from location flexibility?

A: Any organization that cannot predict where their next job will be, such as those in the maintenance/repair, mechanical contractor and construction industries. Because of the ability to connect to almost any input power, welders never have to worry about the type of power they will encounter on their next job. With Auto-Line you can take your welding machine right to where the work is, eliminating the need for additional cables that can be heavy and costly. Productivity is also increased by reducing the time it takes to make output adjustments. With the machine next to the operator, running back and forth to make output changes is no longer necessary.

Q: How do I determine which Auto-Line product is right for me?

A: It all depends on the job for which the machine will be used. The XMT® 350 and Spectrum® 2050 are often used on construction and maintenance sites that need heavy-duty welding and cutting needs. The Maxstar® 200, Maxstar® 150 and Dynasty® 200 are often used for light-duty maintenance, repair and fabrication for in-plant applications.

|

Mechanical contractors, such as this one welding on-site in a food-related application with the Maxstar 200, benefit from Auto-Line because they can’t predict the location of their next job.

|

Q: Which Miller products feature the on-site location flexibility of Auto-Line technology?

A: Several inverters combine Auto-Line with lightweight portability:

* XMT 350 cc/CV inverter (190 V-630 V, 1- or 3-phase, 50 or 60 Hz)

* Spectrum 2050 and 1000 plasma cutter (190 V-630 V, 1- or 3-phase, 50 or 60 Hz)

* Dynasty 200 AC/DC TIG inverter (120 V-460 V, 1- or 3-phase, 50 or 60 Hz)

* Maxstar 200 DC TIG/Stick inverter (120 V-460 V, 1- or 3-phase, 50 or 60 Hz)

* Maxstar 150 DC TIG/Stick inverter (115 V-230 V, 1-phase, 50 or 60 Hz)

* Millermatic® Passport™ MIG Welder (115 V-230 V, 1-phase)