A traditional power source uses a transformer to turn high voltage, low amperage primary power into the low voltage, high amperage power used for welding. An inverter power source takes input power, filters it to DC, and, using fast solid-state switches, increases its frequency up to 20,000 to 100,000 Hz, and then transforms it into useable welding power with an advanced level of control over the arc.

With inverter technology comes the capability for high speed pulsing in DC mode. In AC mode, an inverter offers waveform shaping with more control for optimal results. We’ll take a look at some of the benefits behind these additional capabilities and how you can put them to use.

DC Pulsing

Pulsing refers to switching from a peak amperage to a lower background amperage. This process is useful on ferrous metals whenever welding heat input must be minimized or penetration has to be accurately and repetitively controlled. For out-of-position welding, pulsing may prevent weld metal sagging or drop through. In addition, thin metals can be welded with less distortion.

|

| Inverters with advanced controls allow users to tailor the arc to their needs. |

“On thin stainless, a lot of times you use a pulse just as a way to strengthen the arc. Instead of having the tendency to want to spread out, pulsing focuses the arc,” says Bob Haye, Bob Haye’s Precision Welding, who specializes in welding needs for the aircraft and defense industries.

High speed pulsing can also lead to faster travel speeds. When H.L. Lyons, a refrigerator door fabricator in Louisville, Ken., switched from conventional to inverter TIG technology, they cut welding time in half, reduced finishing time by a third and allowed each welder to finish almost twice as many products per shift.

Traditional technology usually allows for 1 to 10 PPS. A common range for an inverter is 100-500 PPS, which provides increased penetration, arc stability and travel speeds. More advanced inverter power sources, such as the Miller Dynasty 350 and 700, can pulse at 5,000 PPS, which further enhances stability, increases travel speed and is beneficial in automated applications.

Some inverter power sources allow the user to set the percentage of time spent at peak and background amperage to further control heat input and improve weld bead appearance. Increasing peak-on time increases puddle fluidity and helps to fine-tune penetration. A good starting point is to set peak time to 50-60 percent of each cycle. This can then be adjusted to suit your particular application.

A few inverters allow you to set the background amperage, which affects heat input into the part and helps determine the size of the weld puddle and arc, especially during the background portion of the pulse cycle at low PPS settings. At low pulse frequencies, the background amperage should be high enough to keep the puddle from solidifying; it should shrink in diameter but not solidify. For stainless and carbon steel, a good starting point is 20-30 percent of peak amperage.

|

| “I’ve tried the triangular wave and found a setting that was just able to weld phenomenally on thin material,” said Neal Vesco, of Vesco Metal Craft, shown here working on a quad rugby chair. |

AC Output—Welding Aluminum and Magnesium

Advancements in electronics allowed for the development of the squarewave, which solved the problem of the sine wave arc extinguishing itself. The development of inverter technology took AC control even further, refining the squarewave to a nearly instantaneous transition between polarities, eliminating the need for HF arc stabilization when welding with AC and allowing precise control of AC balance, output frequency and independent EN and EP amplitude control.

AC Output Frequency

Conventional technology limits AC frequency to 50 or 60 HZ, the same as single-phase input power. Inverter technology, however, allows output frequency to be adjusted anywhere from 20 to 400 Hz. Increasing AC frequency provides a more focused arc with increased directional control and a narrower bead and cleaning area. A lower frequency softens the arc and results in a wider weld puddle and bead.

An arc cone at 400 Hz is much tighter and more focused at the exact spot the electrode is pointing than an arc cone operating at 60 Hz. The result is significantly improved arc stability and increased penetration, ideal for fillet welds and other fit ups requiring deep, precise penetration.

AC Balance Control

AC Balance Control adjusts the balance between penetration (EN) and cleaning action (EP). Inverter-based TIG welders allow the operator to set the amount of EN from 30 to 99 percent for greater control and fine-tuning of the cleaning action.

|

| Too much cleaning action can lead to the tungsten tip balling. |

More cleaning action is not necessarily better. To produce a good weld, you need only a .1-in. etched zone surrounding the weld, although different joint configurations may have different requirements. Using the least amount of cleaning action (setting the balance at the highest practical EN) necessary helps maintain the tungsten point, reduces balling and provides for deeper, narrower penetration.

Insufficient cleaning action results in a “scummy” weld puddle. If the puddle looks like it has black pepper flakes floating on it, add more cleaning action to “blast” away oxides and other impurities. Too much cleaning action can lead the tungsten tip to ball and reduce penetration. A good starting point is 75% EN. Fine tune it from there.

Amplitude Control

Independent amplitude control, available only on some inverters, allows the EN and EP amperage values to be set independently. Independent control of the EN and EP portions of the AC cycle allows the operator to direct more or less energy into the work piece, as well as take heat off the tungsten.

For example, when welding a thick piece of aluminum, the operator can put 250 amps of EN into the work and only 60 amps of EP into the tungsten. This provides faster travel speeds, faster feed of filler rods, deeper penetration, and the potential to eliminate pre-heating. Some companies cut production time by up to two-thirds using this technology.

Independently increasing EN amperage while maintaining or reducing EP amperage also narrows the arc cone, lets the operator use a smaller diameter electrode to make narrower welds and may allow the use of straight argon in place of argon/helium.

Waveforms

Some inverters also bring control over the waveform itself to meet a specific requirement or operator preference. Some of the waveforms include:

- Advanced Squarewave, which gives fast transitions for a responsive, dynamic and focused arc for better directional control.

- Soft Squarewave, which provides a smoother, softer arc with a more fluid puddle than the squarewave.

- Sine wave, which gives the soft-arc feel of a conventional power source, while using square transitions to eliminate the need for continuous HF.

- Triangular wave, which combines the effect of peak amperage while reducing overall heat input. Leads to quick puddle formation and, because of lowered heat input, reduced weld distortion, especially on thin material.

Achieving maximum productivity often depends on the inverter’s ability to produce a weld bead profile and characteristics that meet the application needs without over-welding, under-welding, excessive post-welding grinding or weld repair. In critical or high-volume applications, only advanced AC controls provide this benefit.

|

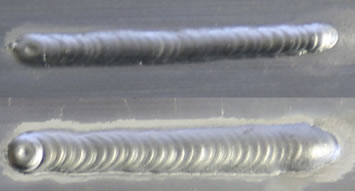

| Two arcs one at 150 HZ and one at 40 HZ. Note the thinner weld bead at the higher frequency and the wider one at the lower frequency. |

"With the Dynasty [an inverter based AC/DC TIG power source by Miller Electric], you can weld much quicker," says Derek Grundler, production manager of A1A Dock Products, Hollywood, Florida. "And when you strike an arc, it draws a puddle at least twice as fast as conventional TIG."

Grundler found that the inverter-based TIG source increased production by 18 percent, provided a payback time of two weeks per machine and improved weld bead consistency. Neal Vesco of Vesco Metal Craft, leading manufacturer of rugby wheelchairs, found production increased by approximately 30% by switching to an inverter based TIG power source, finding the triangular wave especially

useful on thin aluminum. Both Grundler and Vesco also noted an improvement in bead appearance.

"We only have a 1/8-in. white line (etched zone) around the weld," says Grundler. Describing how the new system eliminated post-weld cleanup requirements and protected the aluminum finish. "With conventional TIG, no matter what you do, you're going to get a 1/4-in. white line around the weld."